Measuring Instruments

Introduced a variety of indispensable measuring instruments so as to ensure high-precision. Guaranteeing customers credibility due to varier measuring instruments than processing machines.

PICK UP MACHINE

-

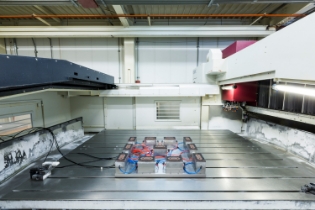

Huge Coordinate Measuring MachineHuge Coordinate Measuring Machine

Name MMZ-G30/60/20 (ZEISS) Measurement range X:3000 x Y:6000 x Z:2000mm The largest size, the MMZ-G 30/60/20 manufactured by Carl Zeiss in Germany, boasts world-class measurement accuracy with a maximum allowable error of less than 12μm (guaranteed value by manufacturer) at a maximum length of 6000mm. A stone surface plate of the same size as the measurement range is installed to minimize the influence of the ground surface, enabling stable measurement. Measurement can be made while working on the stone surface plate for assembly of optical products, making it extremely effective in guaranteeing high-precision parts.

-

Large Coordinate Measuring MachineLarge Coordinate Measuring Machine

Name PRISMO10(ZEISS) Measurement range X:1600 x Y:2400 x Z:1000mm

-

Large Coordinate Measuring MachineLarge Coordinate Measuring Machine

Name PRISMO7 JV VAST(ZEISS) Measurement range X:1600 x Y:2400 x Z:1000mm

-

Coordinate Measuring MachineCoordinate Measuring Machine

Name XYZAX FUSION NEX 10/15/8(TOKYO SEIMITSU) Measurement range X:1000 x Y:1500 x Z:800mm

-

Coordinate Measuring MachineCoordinate Measuring Machine

Name ACCURA Ⅱ 16/30/15 VAST(TOKYO SEIMITSU) Measurement range X:1600 x Y:3000 x Z:1500mm -

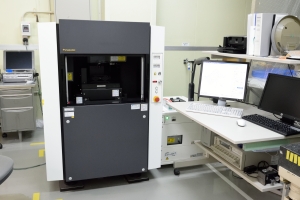

High-precision Coordinate Measuring MachineHigh-precision Coordinate Measuring Machine

Name UA3P(Panasonic) Measurement range X:100 x Y:100 x Z:35mm

Atomic force probe enables scanning measurement with minimal damage to the workpiece surface. In addition to flat surfaces and spherical surfaces, rotationally symmetric aspheric surfaces and rotationally asymmetric aspheric surfaces can also be measured.

Compared to non-contact measurement, lenses with anti-reflection coating can also be measured, and tilts of up to 60° can be measured. Position detection on the X, Y, and Z axes uses laser interferometry using a high-precision reference mirror to capture data to cancel the effects of stage straightness, making highly accurate measurements possible. Its reliability is highly evaluated all over the world. -

Large Caliber (12″) Laser interferometerLarge Caliber (12") Laser interferometer

Name VeriFire Atz(Zygo) Measurement range phi300mm

Equipped with functions such as high spatial resolution, interference noise suppression, and vibration correction, it enables highly accurate and reliable measurement of the shape accuracy of the surface to be measured.

-

Non-contact Surface Texture Measuring MachineNon-contact Surface Texture Measuring Machine

Name NewView8300(Zygo) Magnification x1.375 to x100 Measurement range x1.375: 6.05x0.05mm

x100: 0.08x0.08mm

-

Non-contact Surface Texture Measuring MachineNon-contact Surface Texture Measuring Machine

Name NanoCam sq(4D technology) Magnification x5 to x100:(1.4x1.0mm)/(0.07x0.05mm) -

Tactile Surface Profile and Roughness Measuring InstrumentTactile Surface Profile and Roughness Measuring Instrument

Name Form Talysurf Super S5K(AMETEK) Measurement range 120mm (Straight line)

Machining

Machining Whetstone Grinding

Whetstone Grinding Polishing / Lapping

Polishing / Lapping Ultra-precise Processing

Ultra-precise Processing