History

Challenge from the garage Company

Path to the ultra-high-precise processing technology

based on the skill of a master craftsman

Started in Garage

Set up a business as polishing craftsman with the hand-polishing skill for optical single-crystals as strength.

- April 1985

-

Crystal Optics Ltd. established and founded.

Independently established as single crystals polishing craftsman.

Built less than 15 square meters workshop above garage in founder’s house and started business. Polished only palm-sized substrates, mainly hand-polishing, possessing a small lathe and an Oscar polishing machine. Possessed a much-needed lapping machine six months later.

Commenced mass production of mirror finishing to support state-of-the-art technology.

Undertook to polish parts made of special materials such as semiconductor and the like.

- 1986

Completed a new factory and transferred head office.

Took up polishing indispensable parts for semiconductor and stainless parts of mass flow meter. This was an opportunity to enter into semiconductor industry.

- September 1989

Started processing other than crystals and stainless steel (materials such as metals, ceramics, glasses, and new materials).

- January 1990

Built tentative factory in Kumamoto prefecture.

Prepared for mass production of mass flow controller.

- March 1990

Established Crystal Optics Inc.

Changed from limited company to a stock company to reinforce organizational structure, aiming to expand business.

- October 1990

-

Relocated into a new factory and commenced polishing mass production parts of mass flow meter.

Minamisho head office

Minamisho head office Minamisho second factory

Minamisho second factory Former Kumamoto factory

Former Kumamoto factory

Aiming integrated manufacturing system.

The beginning of integrated manufacturing system owing to machining, whetstone grinding, Lapping, and Coordinate Measuring Machine.

Took up processing long metal product and large sized plate product.

- July 1997

Completed another new factory to install very big equipment and relocated into a present head office.

- July 1998

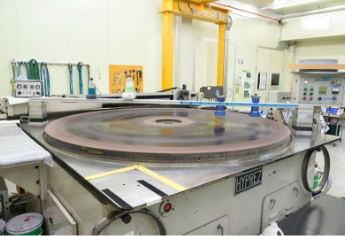

Installed big sized lapping machines (two 2-meter-sized lapping machines).

- December 2001

Completed integrated manufacturing system owing to installation of machining, gate-type whetstone grinding machine, and Coordinate Measuring Machine.

Started high precise processing.

- May 2002

-

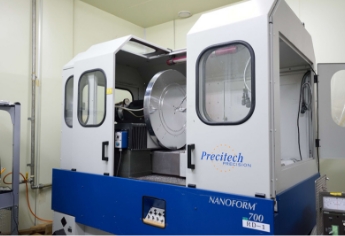

Installed diamond turning machine.

Made us be viable to finish with mirror surface on the spherical and aspherical shape. Head office

Head office 2-meter-sized lapping machine

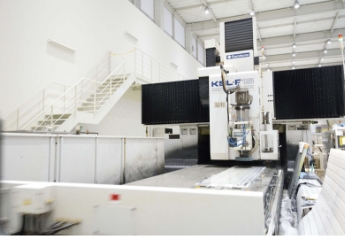

2-meter-sized lapping machine Gate-type whetstone grinding machine

Gate-type whetstone grinding machine Diamond turning machine

Diamond turning machine

Foothold to be able to process huge and high precise product.

Installed huge and high precise processing machines.

- July 2003

Completed Otsu factory as a huge factory. Installed 5-meter-sized gate-type whetstone grinding machine, 3.2-meter-sized lapping machine, and 2.4-meter-sized Coordinate Measuring Machine.

- April 2005

Acquired ISO14001 certification.

- June 2007

-

Accredited one of good 300 small and medium enterprises by The Small and Medium Enterprise Agency in Ministry of Economy, Trade and Industry.

Otsu factory

Otsu factory 5-meter-sized gate-type whetstone grinding machine in Otsu factory

5-meter-sized gate-type whetstone grinding machine in Otsu factory

Achieving to process huge product with ultra-high-precision assurance.

Aiming to break into space & astronomical industry.

- April 2009

Completed Kyoto factory to serve huge sized parts in aviation industry.

Installed a huge-sized Coordinate Measuring Machine, a huge-sized gate-type 5-axis machining, and huge-sized high accuracy whetstone grinding machines.

Started entering into electropolishing and passivation for semiconductors.

- April 2009

Relocated Kumamoto factory.

Commenced electropolishing and passivation for semiconductors adhering SEMI standard.

- March 2013

Acquired ISO9001 and JIS Q 9100 at the same time in Kyoto factory.

ISO 9001 International Standard for Quality Management Systems

JISQ 9100 Quality Management System Standard for the Aerospace Industry

- April 2016

Opened Shinyokohama sales office.

- July 2017

Extended Kyoto factory.

- January 2018

Acquired KES step2; Kyoto environmental management system standard.

- September 2018

Completed latest Kumamoto factory.

- April 2019

Acquired ISO9001 in head office factory, Otsu factory, Kumamoto factory, and Shinyokohama sales office.

- June 2019

Acquired Kiyohara Optics as a subsidiary

- August 2019

-

Completed Kyoto second factory.

Expanded the range of Kyoto factory operations. Completion of latest Kumamoto factory

Completion of latest Kumamoto factory Completion of Kyoto second factory

Completion of Kyoto second factory

- February 2022

Extended Kumamoto factory.

- October 2023

-

Opened Vietnam representative office

Vietnam representative office

Vietnam representative office